Titanium is just one of the many alloys we treat at The Lux Group. The electropolishing process makes titanium parts last longer and performs better. Titanium’s natural resistance to corrosion and high temperatures, as well as its high tensile strength and biocompatibility, make it a popular alloy in aerospace, medical and marine applications. By electropolishing titanium parts, we improve performance while maintaining the properties that make this alloy unique.

BENEFITS OF ELECTROPOLISHING TITANIUM

Electropolishing titanium improves the alloy’s natural corrosion resistance and biocompatibility by performing several operations at once. Titanium polishing by means of electropolishing provides the following benefits:

- Corrosion Resistance: electropolishing titanium removes the outer skin of metal, eliminating micro-surface imperfections that could become initiation sites for corrosion.

- Microfinishing: by removing 001” to .002” material from the thickness or diameter of a part you will improve the Ra value by as much as 50%. Since the electropolishing process is a rack process, it is compatible with fragile parts that don’t lend themselves to conventional finishing methods. Our electropolishing process will not distort or change the shape of your part which is not the case with mass finishing.

- Deburring: titanium parts used in medical applications must be burr-free. Electropolishing medical devices is an effective deburring operation that leaves the surface free of micro-imperfections that can otherwise impede performance.

- Ultracleaning: electropolishing titanium medical devices and other parts made from this alloy removes residual debris and other embedded contaminants. This comprehensive cleaning operation is used for critical implantable medical devices like dental and surgical implants, which must be bacteria-free before use. For highly visible metal parts, like surgical tools, it also creates a clean, bright and decorative surface.

Due to the multiple benefits of electropolishing, it is a more effective and versatile process than passivation and other traditional titanium polishing processes alone. You’ll see the difference in the improved fit and function with the electropolished parts that have undergone sufficient deburring, ultra cleaning, and micro finishing.

THE TITANIUM POLISHING PROCESS THROUGH ELECTROPOLISHING

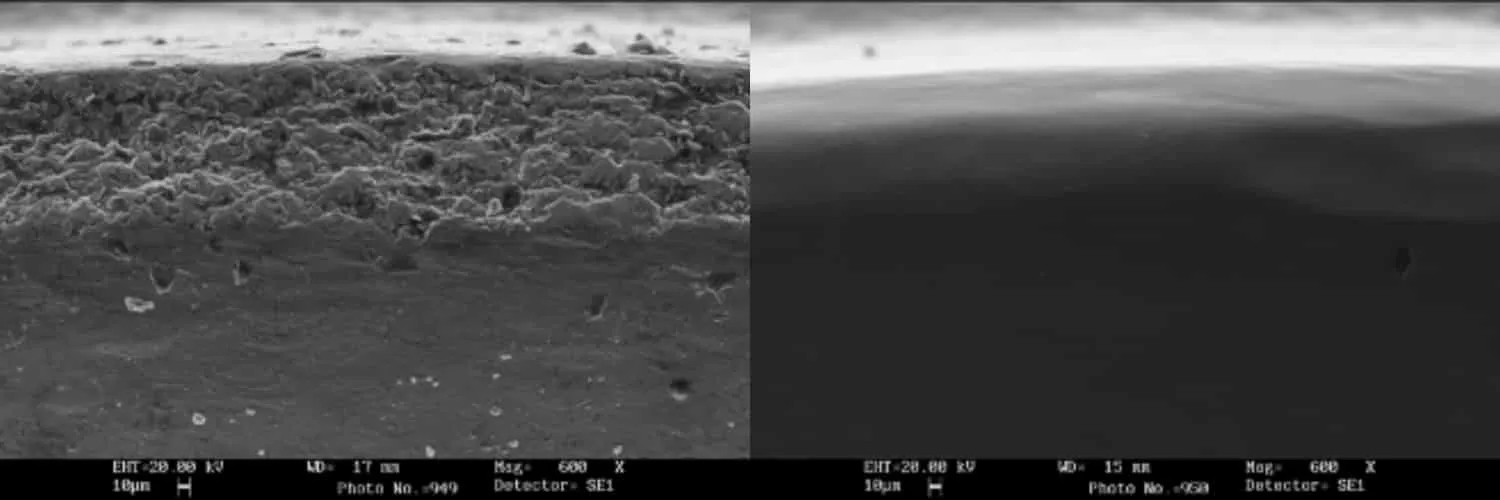

Titanium electropolishing is an electrochemical process that removes a controlled amount of surface material from the outer layer of a part. Removing this material eliminates surface imperfections, embedded contaminants, sharp edges and burrs, and micro cracks and pits that could lead to corrosion. The surface it leaves behind is smooth, highly corrosion resistant and free of the imperfections that compromise strength and longevity. Electropolished titanium parts are also left with a distinct and lasting shine ideal for consumer products.

SIZING TITANIUM WITH ELECTROPOLISHING

Titanium is frequently used to make parts with little-to-no margin of error, like landing gear, hydraulic systems, rotors, valves and more. When parts like these are even a small fraction of an inch out of tolerance, they are unusable. Electropolishing titanium is an ideal sizing operation that allows you to bring a part into size with precision and without altering shape or proportions. Because the process removes a uniform amount of surface metal from the entire part, it is practical even for small and complex parts. This process can remove as little as .0001″, giving you a high level of control and ensuring that your parts are sized according to your needs.

ELECTROPOLISHING VS. PASSIVATION

Electropolishing provides superior results for titanium when compared to passivation. While passivation eliminates contaminants from the metal’s surface, it doesn’t remove embedded contaminants from the pores or imperfections in the metal. Passivation does not give you value-added aesthetic that electropolishing does, and electropolished parts are passivated as part of the process.

With that in mind, choosing electropolishing is the way to ensure the metal parts used are safer, longer lasting, and better suited for critical applications.